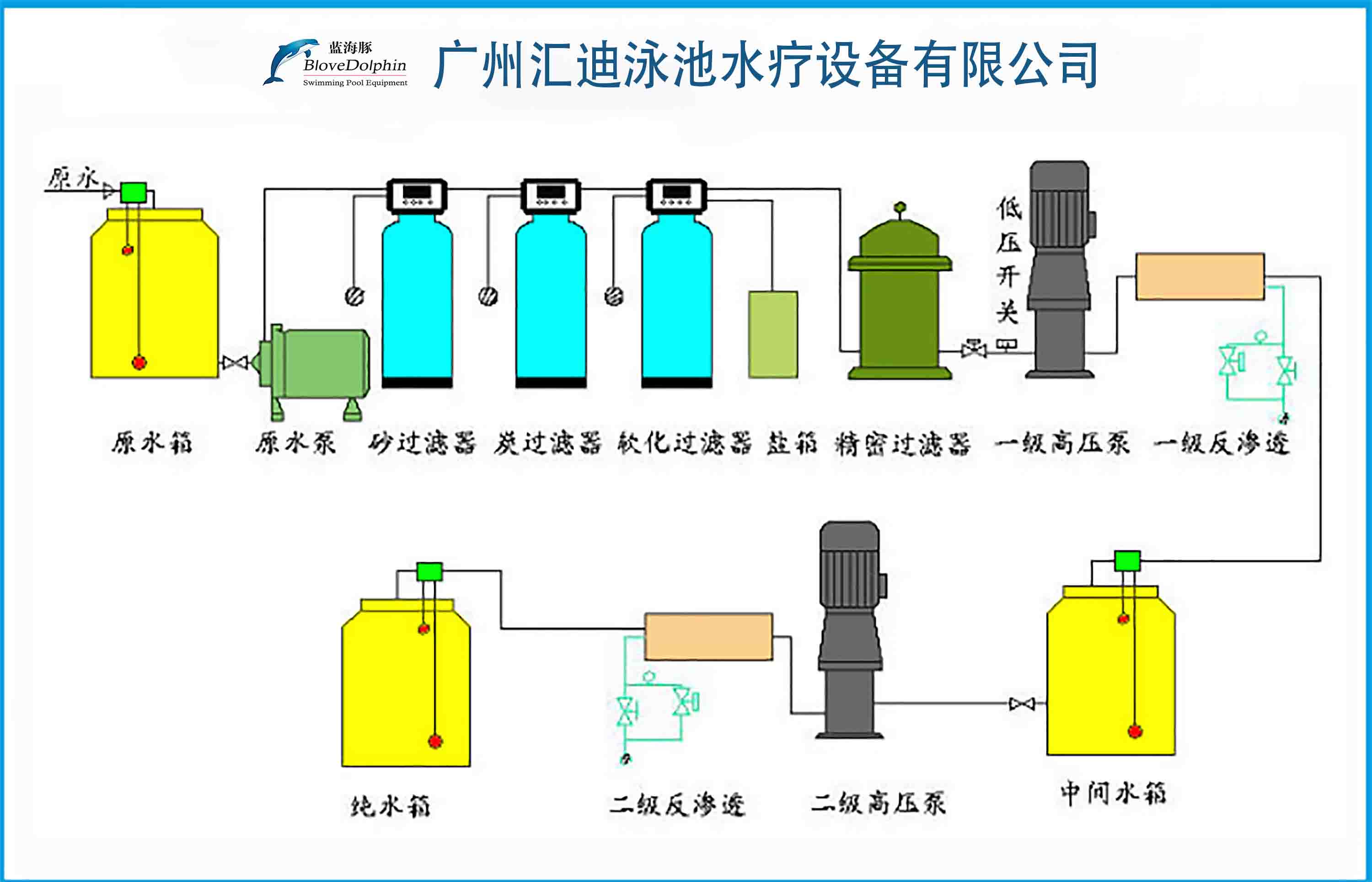

Reverse Osmosis System Process Flow and Description

1. The raw water tank stores raw water, buffering the impact of unstable raw water pipe pressure on the water treatment system. It is also used to settle larger sand particles and other settleable substances in groundwater.

2. Coagulant addition: This mainly removes smaller suspended colloids in the water. Because these tiny particles will not settle in the water under the action of gravity and are difficult to remove in subsequent filters, the raw water needs to undergo coagulation treatment. This is achieved by adding coagulants to the raw water to form larger flocs of suspended matter and colloids, which are then removed by filtration through a multimedia filter. When the iron content in the raw water is less than 0.3mg/L and the suspended solids content is less than 20mg/L, this device can be omitted as pretreatment. When the content of suspended matter and colloids in the water is high, a coagulant addition device is generally required.

3. The raw water pump maintains a constant water supply pressure and stable water supply volume for the system.

4. The main function of the multi-layer filter is to remove particles larger than 20um in the raw water, such as sand, rust, colloids, and suspended matter. It can be controlled by manual valves or an automatic controller to perform backwashing, forward washing, and other operations. This ensures the water quality of the equipment and extends its service life.

5. This can remove free chlorine and organic matter in the water to protect the reverse osmosis equipment. Free chlorine will oxidize and damage the reverse osmosis membrane; reverse osmosis generally requires the incoming water chlorine to be less than 0.1ppm; organic matter is not only the nutrient for microorganisms, but also when the concentration reaches a certain level, it will dissolve the organic membrane material, reducing the performance of the membrane. Various organic substances exist in water, and different organic substances have different harms to the reverse osmosis membrane. Therefore, in the design of the reverse osmosis pretreatment system, if the total organic carbon (TOC) content in the water exceeds 2mg/L, it generally needs to be treated. For purification systems using tap water as a water source, because the surface water contains a higher content of organic matter, activated carbon adsorption is required.

6. The role of the water softener/chemical descaling device is to prevent insoluble salts from scaling on the surface of the reverse osmosis membrane. Softening is the process of removing calcium and magnesium ions from water through ion exchange resin. The advantage of softening is that it can completely remove calcium and magnesium ions in the water, preventing these ions from scaling in the reverse osmosis equipment. The disadvantage is that the equipment investment is high, and regeneration is required after running for a period of time.

7. The precision filter, also known as the security filter, is used to intercept particles larger than 5 microns in the raw water to prevent the reverse osmosis membrane from being scratched by large suspended particles. Because the thickness of the reverse osmosis membrane is about 10 microns, larger particles in the raw water can easily scratch the desalination layer on the surface of the reverse osmosis membrane, or penetrate the reverse osmosis membrane component under the acceleration of the high-pressure pump. Therefore, a 5-micron precision filter is generally installed before the reverse osmosis equipment.

Reverse Osmosis Pure Water Equipment Operating Parameters and Water Output Indicators

1. Single-unit output: 0.25M3/H-100 M3/H (customized according to customer needs).

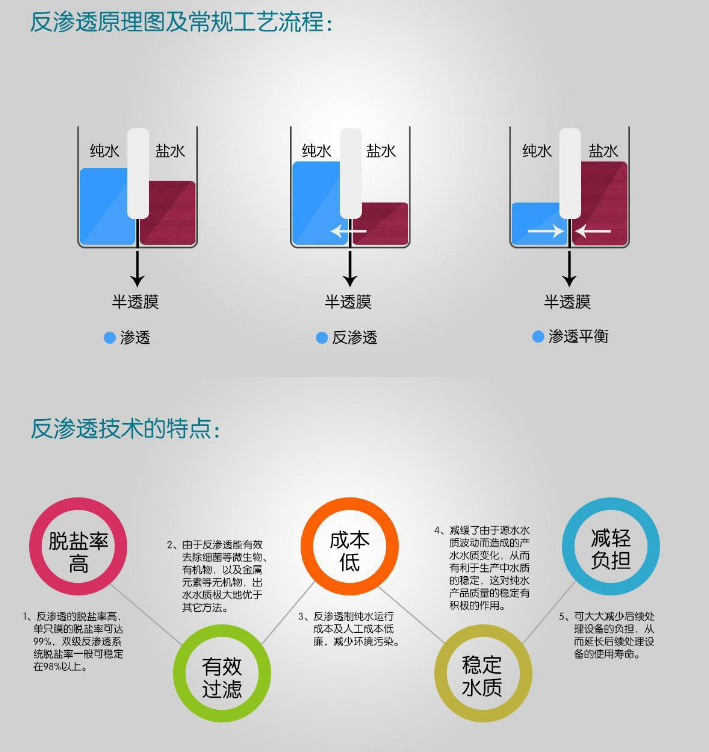

2. Desalination rate: Reverse osmosis system >98% (single-stage or two-stage reverse osmosis device customized according to process requirements).

3. Operating pressure: 1Mpa-1.5Mpa.

4. Recovery rate: 50%-75%.

5. Product water conductivity: <10 μs/CM (raw water <500 μs/CM)

Keywords

Blue Dolphin - Soft Water Filter

Contact Us

Classification

Let's collaborate to build a better future together!

Shop 1, 2, 3, No. 31 Nan'an Road, Nanyuan Street, Liwan District, Guangzhou City

Copyright © 2025 Guangzhou Huidi Swimming Pool Spa Equipment Co., Ltd 丨 SEO