Equipment Parameters

Equipment Parameters

| Serial Number | Item | Specific Description |

| 1 | Equipment Model | HD-B650 |

| 2 | Power Supply | Three-phase five-wire 380V, 50HZ, |

| 3 | Shredder Motor Power | 1400RPM 3HP AC380V |

| 4 | Separation Motor Power | 1400RPM 2.2HP AC380V |

| 6 | Peristaltic Pump | 100RPM DC24V |

| 7 | Dimensions | 740mm*740mm*900mm(H) |

| 8 | Processing Capacity | 650kg/hr |

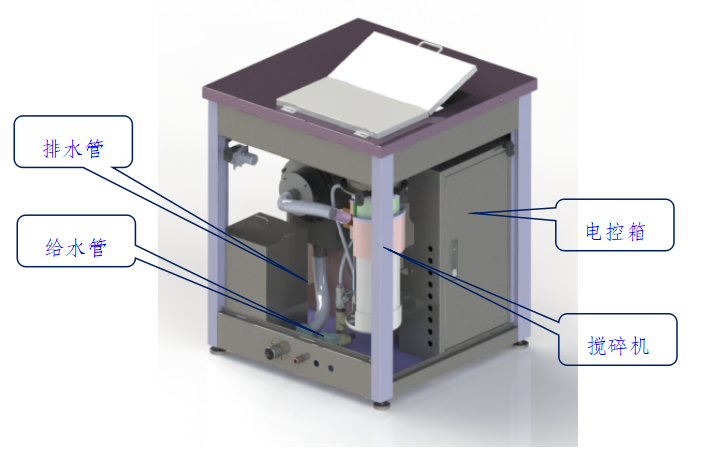

| 9 | Water Supply Pipe | 1/2 Inch |

| 10 | Drainage Pipe | 1 1/2 Inch |

| Drying System | Screw-type Heater (To be configured separately according to customer needs) |

Working Principle

Working Principle

(Operating Status)

1. The operator turns on the power, presses the start switch, the shredder motor and the separation motor start slowly at the same time, the water supply solenoid valve opens, and the peristaltic pump draws medicine;

2. The operator pours the food waste from the inlet, and the shredded food waste mixed with tap water enters the centrifugal dehydrator from the tail end through the pipeline;

3. The shredded solid-liquid mixture is separated under the action of centrifugal force, the liquid is discharged into the municipal sewage pipe network from the water outlet at the tail end of the centrifuge, and the solid is discharged into the receiving box from the front end outlet under the action of the screw.

(Cleaning Status)

1. The operator turns on the power, presses the cleaning switch, the shredder motor and the separation motor start slowly in reverse at the same time, the water supply solenoid valve opens, and the automatic cleaning work is performed;

2. The wastewater generated during cleaning is discharged into the municipal sewage pipe network from the water outlet at the tail end of the centrifuge.

Main Component Description

Main Component Description

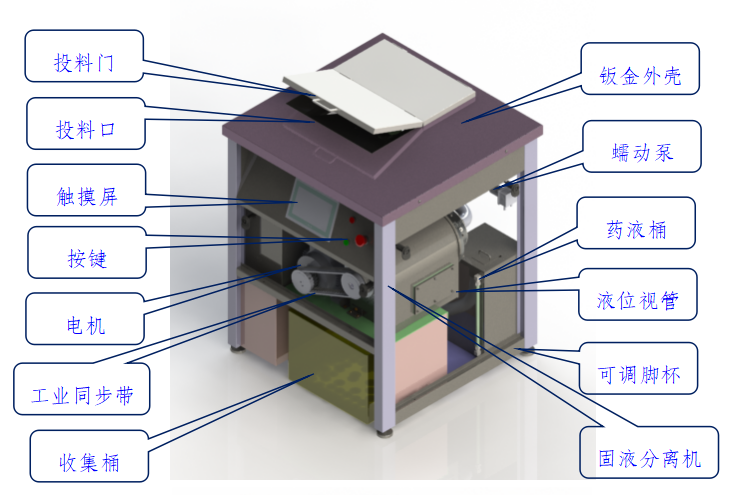

The machine is mainly composed of five major parts: sheet metal part, shredding part, centrifugal dehydration part, electrical part and pipe fitting part:

1. Sheet metal part: All use single-sided brushed SUS304 processing, the grade is 0Cr18Ni9, with good mechanical processing performance and excellent corrosion resistance.

2. Shredding part: The motor is 380V 1400RPM 3HP, the shredding cutter head and shredding cutter plate are integrally processed with SUS420 and then heat-treated, and the hardness can reach the range of 55HRC-60HRC.

1. Centrifugal dehydration part: The motor is 380V 1400RPM 2HP, the motor and the centrifuge body are connected by synchronous wheels and synchronous belts, high-speed rotating centrifugal dehydration, and a speed difference is automatically formed by the difference in the number of teeth between the synchronous wheels to automatically discharge materials.

2. Electrical part: It adopts PLC control, human-machine interface operation, mechanical button auxiliary and other electrical components to form a humanized, automated, and intelligent operating system; the system can be customized programmed according to actual operation needs to achieve fully controllable operation.

3. Pipe fitting part: Mainly uses 0.5Inch and 1.5Inch hoses and pipe fittings.

Product Images

Product Images

Keywords

Blue Dolphin food waste reduction processor

Contact Us

Let's collaborate to build a better future together!

Shop 1, 2, 3, No. 31 Nan'an Road, Nanyuan Street, Liwan District, Guangzhou City

Copyright © 2025 Guangzhou Huidi Swimming Pool Spa Equipment Co., Ltd 丨 SEO